At Original Engines Co – Clean environmental influences on our manufacturing processes are extremely important to us and how we can lessen impact on the environment and show we continue our legacy with establishing improvements of our carbon footprint.

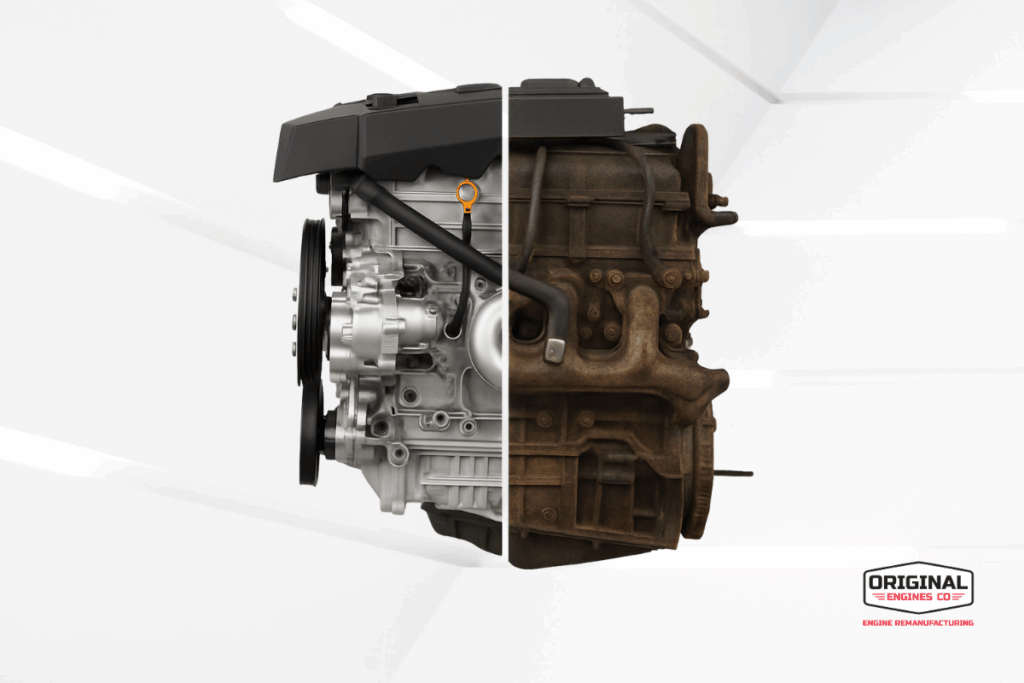

Engine Remanufacturing is, in itself, an important form of recycling and we are very proud of the fact that our processes enable us to return/recycle engine components with detail processes back to their original OEM state, and ready for reuse.

To ensure the environment is at the forefront of our manufacturing procedures, we acquired ISO14001:2015 Environmental as part of our Integrated Management system. But we didn’t stop there!

We invited GreenCap, an off shoot of the Environmental Protection Agency (EPA) to visit our facility and carry out an environmental audit of our awesome structure in Kilsyth, this to ensure our environmental practices were up to date and to receive feedback in areas of improvements that could be made. The EPA Auditor was extremely impressed, and we passed with flying colours. But, we didn’t stop there either!

We are continuing to decrease our environmental impact in many ways, here are some of our other practices:

- The removal of Caustic harsh chemicals, Petrochemicals Diesel & Kerosene, replaced by ‘soft’ environmental chemicals that are kind to the environment

- Our unique Triple Interceptor system captures waste contaminants and recycles water thus complying with the Trade Waste Community ensuring our sewer system and waterways remain clean.

- We have an internal facility to collect waste oils for recycling.

- Newly implemented Hot Component Wash Systems and State of the Art Ultrasonic Cleaners use chemicals that are biodegradable and environmentally friendly.

- All cardboard, paper, plastic and scrap metal/alloy is recycled

- Oil rags are washed and recycled on a weekly basis

Implementation of new technology with a positive filtered air system producing air flow through the main manufacturing facility with attributes of normalised climate stability and fresh filtered air encouraging elements of OH&S for all our staff

The proposed implementation of Clean Energy Solar Power to further decrease our carbon footprint and supply of energy back into the grid.