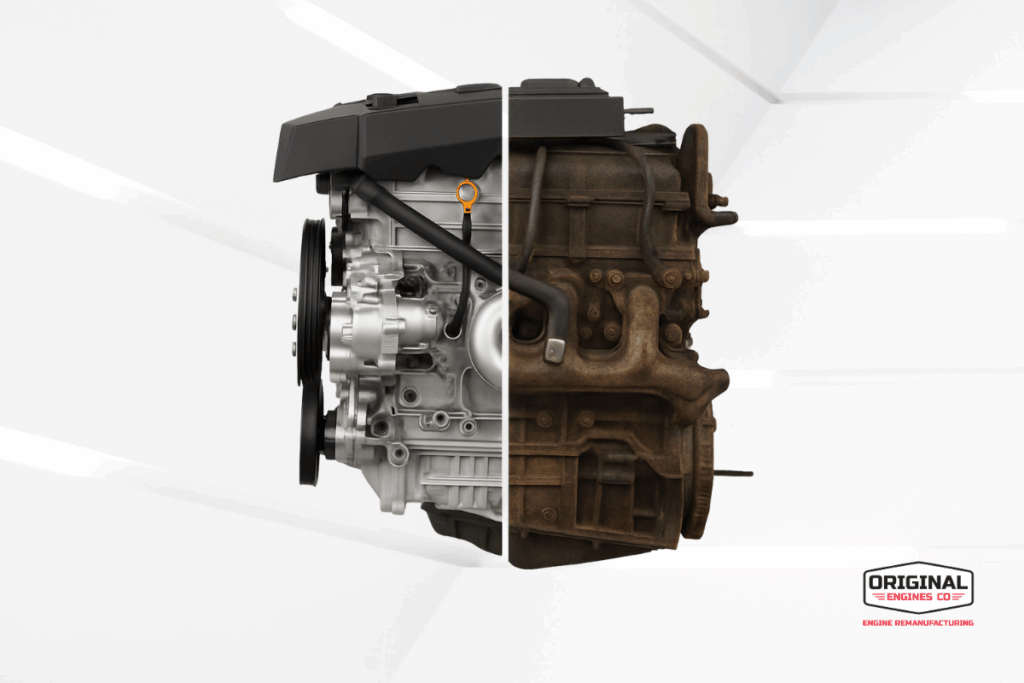

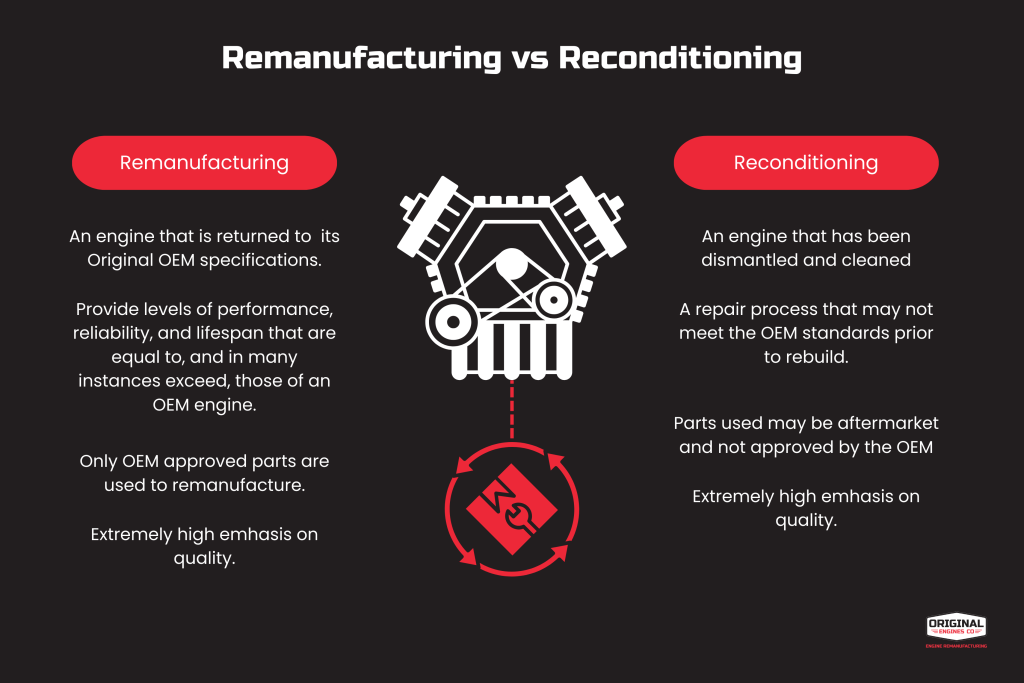

Often, people will mistake engine remanufacturing and reconditioning as the same thing. Whilst there are many similarities between engine remanufacturing and reconditioning, the end product is greatly different, especially in the eyes of the industry and OEMs. As Australia’s leading engine remanufacturer, we will breakdown the key differences and highlight the benefits of a remanufactured engine.

To put it simply, a reconditioned engine is an engine that has suffered internal damage or component failure that is then stripped-disassembled, cleaned, rebuilt with non-genuine aftermarket components and a repair process that may not meet OEM standards prior to being rebuilt.

In contrast, a remanufactured engine has been returned to the vehicle manufacturer’s original factory specification using all OEM factory genuine parts. As a result, remanufactured engines provide levels of performance, reliability and lifespan that are equal to and, in many instances exceed, those of an OEM product. As well, a remanufactured unit will come with a warranty that can be equal to a brand new core.

Remanufacturing vs Reconditioning

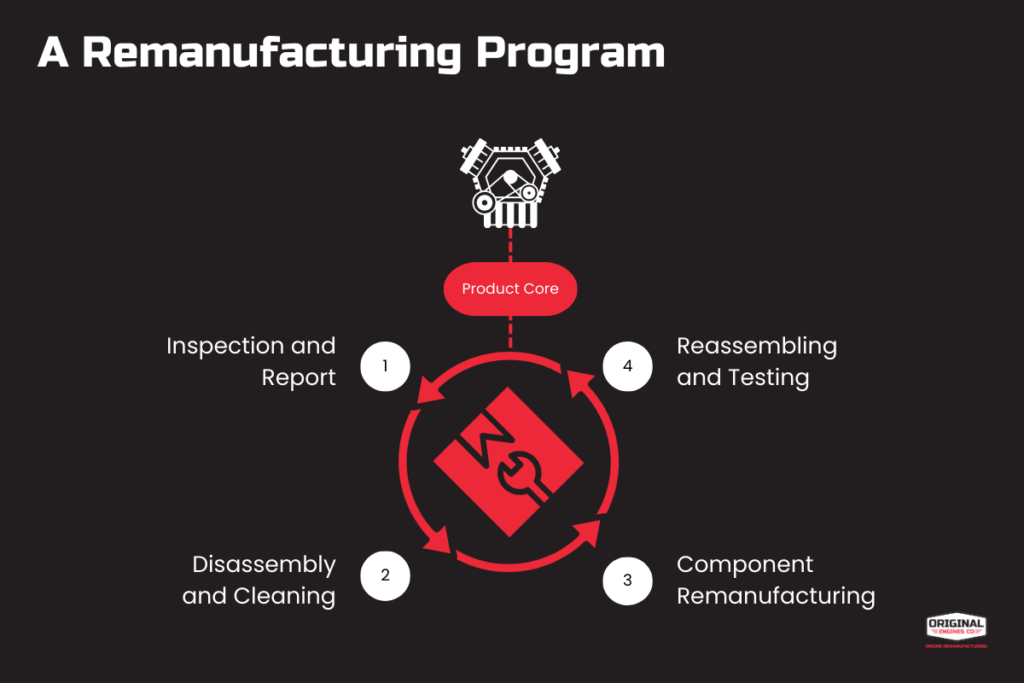

Original Engines Co has a tailored remanufacturing process that includes inspection and checking of components to ensure OEM specifications with components that meet hardness, dimensional, clearance and critical standards.

Furthermore, our remanufactured engines are required to meet OEM specifications with known mandatory components that include the following key parts:

- Pistons and Rings

- Big and Small end Bearings

- All gaskets and oil seals

- Timing chains and belts

- Rocker and Valve assemblies

- Yielded fasteners throughout the engine

There is a greater emphasis on quality for remanufacturing with important machining and assembly operations that are imperative in achieving a remanufactured product. Original Engines Co has a Quality Management System that ensures our customers are provided with a consistently high standard of quality product, reliability and technical service.

Colin Doherty (Dip Mech Engineer & Company MD) comments – “There is still plenty of confusion in understanding the difference between remanufactured and reconditioned engines, believing they are one and the same. When in fact, they’re fundamentally different. Our engines are purposely hand built to Blueprint specifications. Original Engines Co produce to the manufacturers OEM Ford designs and are virtually indistinguishable from “NEW”.

Another important benefit of remanufacturing is that it is environmentally friendly with an average of 65% original engine components being used. We talk more about the environmental and socio-economic benefits of remanufacturing in this article. Original Engines Co is proud to be remanufacturing engines back to their OEM state and contributing to circular economy practices in Australia.