Recycling is widely known and embraced by industries for its environmental impacts and its ability to stimulate an economy. Consumers alike are well aware of recycling as we are introduced to this topic from a very young age. However, when it comes to remanufacturing, the benefits are largely unknown. Arguably, remanufacturing is simply unheard of in comparison to recycling. Both recycling and remanufacturing are important programs in the step-change to a circular economy.

A study commissioned by the The Australian Council of Recycling neatly summarises the economic value of the recycling sector. Here, we will share some of the socio-economic and environmental benefits of remanufacturing, plus the potential for remanufacturing in Australia.

What is remanufacturing?

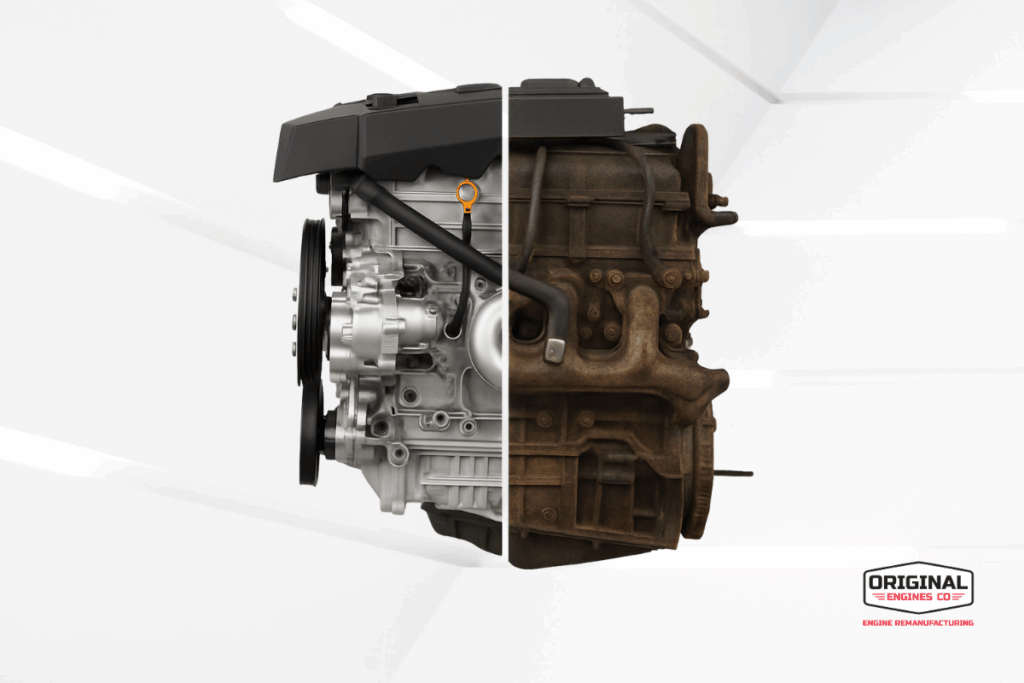

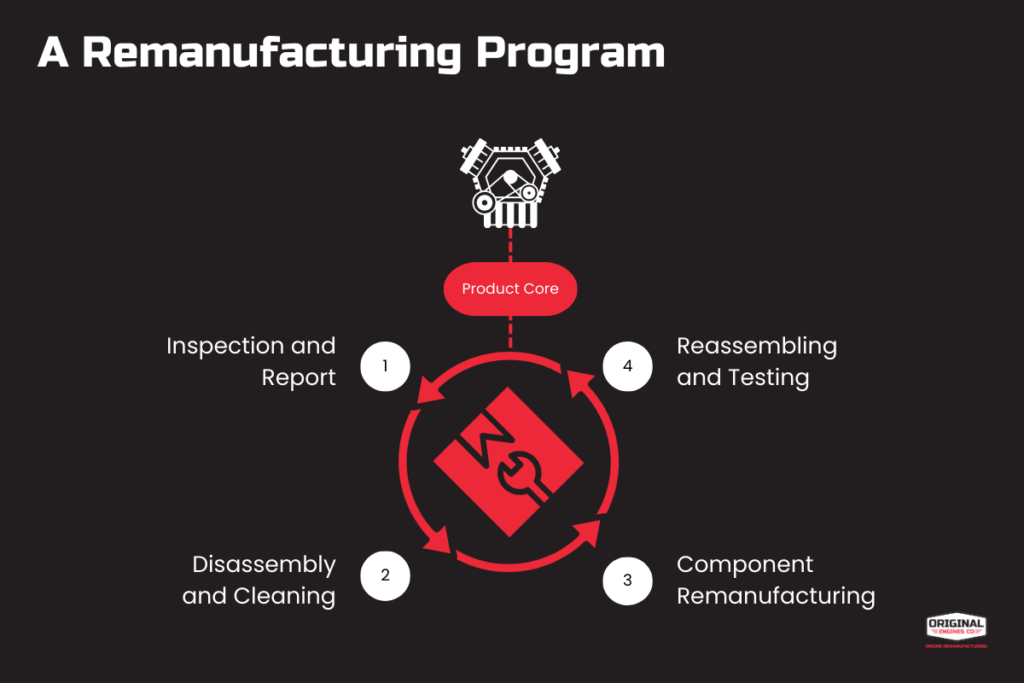

In summary, the process of remanufacturing is to give a product a second life. Many products that have been sold and used are able to be remanufactured back to the Original Equipment Manufacturer (OEM) standard, including a warranty that matches a new counterpart. Additionally, new non-functional or faulty products may also be given a second chance through remanufacturing.

Remanufactured products are different to reconditioned or aftermarket products. Aftermarket products are typically new products that are not produced by the OEM that may come at a cheaper cost than the OEM part. As for reconditioned products, we’ve written a detailed article breaking down the difference between remanufacturing and reconditioning.

Remanufacturing requires a heavy attention to detail and rigorous testing and quality control that is designed to meet the specifications of the OEM.

The Socio-economic impacts of remanufacturing

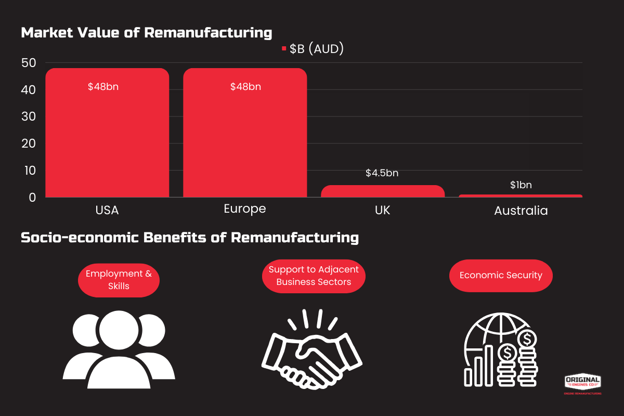

We only need to look to markets such as the UK, Europe, and North America to understand the economic opportunities for remanufacturing. A report from Carbon Trust in the UK cited that remanufacturing in the UK is worth £2.4bn ($4.53 billion AUD), $32bn USD ($48bn AUD) in the USA and €29.8bn ($48bn AUD) in Europe. It is unknown what the exact market value for remanufacturing is for Australia, however if we look at the manufacturing to remanufacturing ratio in other markets, remanufacturing accounts for around 1.1% of total manufacturing. Manufacturing in Australia is an $88bn industry so we can assume that remanufacturing is around $1bn.

Whilst there are several benefits to an economy through remanufacturing, there are three which industries like to highlight as key drivers.

- Stimulating employment with jobs and skills. Remanufacturing requires people with a wide variety of skills, particularly in engineering and mechanics. As well, in most instances there are significant value chains for OEMs to adopt local remanufacturing as opposed to offshore, so where this is viable creates opportunity for employment.

- Business opportunities for adjacent sectors. Parallel industries needed to support a remanufacturing business can benefit too. Such industries are logistics, technology and infrastructure, and education.

- Strengthening and supporting national economic security. Remanufacturing can reduce dependency on material and product imports creating a balance of trade and economic resilience.

The horizon for remanufacturing looks promising. The rising awareness of remanufacturing and the role it plays in the circular economy is gaining the interest of industries and states alike. A European market study into remanufacturing estimates that the size of remanufacturing will more than double by 2030 to €70bn ($114bn AUD).

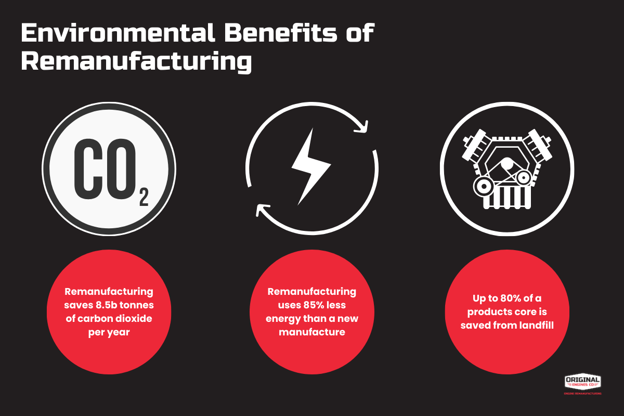

Environmental Benefits

Diverting products away from landfill and averting CO2e emissions are the benefits of remanufacturing that are attractive to industries, governments and consumers.

The same European market study by The European Remanufacturing Network cites that a remanufactured product saves up to 80% of its original core and that remanufacturing as a practice saves 8.5bn tonnes of carbon dioxide a year. Carbon Trust found that remanufacturing on average uses 85% less energy in comparison to a new manufacture. Further to this, a French company was used in a case study to determine the economic and environmental impacts of remanufacturing. They found that the CO2 emissions of their remanufactured products contributed equivalent to only 27% of their manufactured variants.

Remanufacturing plays a big part in the circular economy, with the key distinction between recycling and remanufacturing in that the former only recovers material while the latter recovers products i.e. more value is retained.

The Remanufacturing Opportunity for Australia

Remanufacturing is a win-win for economic growth and better sustainability practices. We estimate the current value for remanufacturing to be around $1bn, which is quite behind our northern hemisphere counterparts. Through awareness and support, remanufacturing could support the current trajectory of manufacturing (currently predicted to have an 8-year CAGR of 3%) to a much higher potential. There is appetite for OEMs in Australia for remanufacturing but a lack of supply to meet the demand.

Original Engines Co is proud to be a leading remanufacturing business in the automotive space and is committed to building the awareness for remanufacturing in Australia. To learn more about our Original Engines Co and our remanufacturing process, we invite you to visit our about us page.